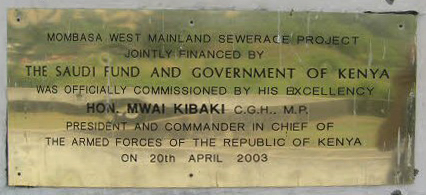

A visit to the Mombasa West Mainland STP, Kenya on 30 July 2007

A photographic impression

Ruud Kampf

Frederick Tettey-Lowor

Very low loaded activated sludge plant (Pasveer ditch), three times 17.000 m3, capacity ca. 200.000 population equivalent

The inlet works with sand traps. A simple, but obvious a simple design. Load about 6000 m3/day or 2400 kg BOD/day, only

A first sight learned something is terribly wrong, there is no sludge in the plant! Just a "milky" substance

Only three of the four settling tanks were in use, but of none the bridge was turning: no sludge return!! And for a long time already, it is even questionable the wheels of the bridges can ever be sued again, while a flat side.

We could really understand when you have to work in a situation like this, you tend to get very frustrated. It is a new and very well designed plant. But when the situation is wrong, what to do! I have made some calculations: link.

Please, mail me about any comments!?

Solutions, several ways of thinking:

A - bring the STP in the same state as in 2003, when opened. This will be possible, without to much effort?

B- As A, but only do that with only one third of the plant, as long as the plant is this heavily under loaded. Start with full load to one channel to grow activated sludge

C - a more simple solution? Transfer the plant into a batch loaded plant, no extra instrumentation, just by hand

Suggestions?